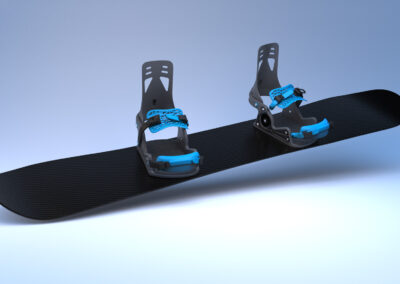

The snowboard binding designed for beginners.

project brief

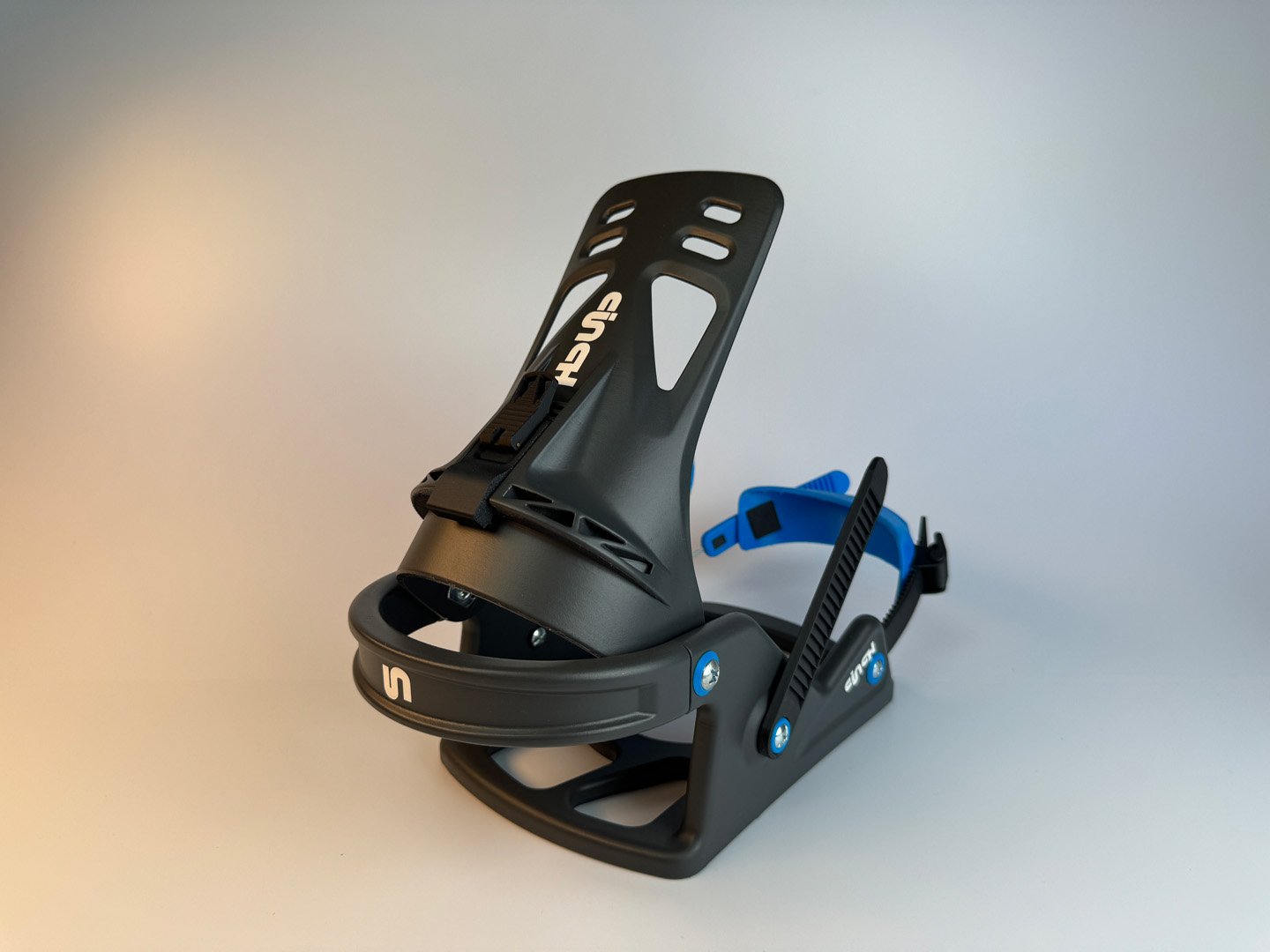

Cinch, my capstone project, focused on designing snowboard bindings specifically tailored for beginners. The goal was to create a product that simplifies the process of entering and exiting the bindings, while considering human factors such as ergonomics, dexterity, and flexibility.

tools

PROCREATE

SOLIDWORKS

KEYSHOT

RHINO

FDM 3D PRINTER

SLA RESIN PRINTER

RESEARCH

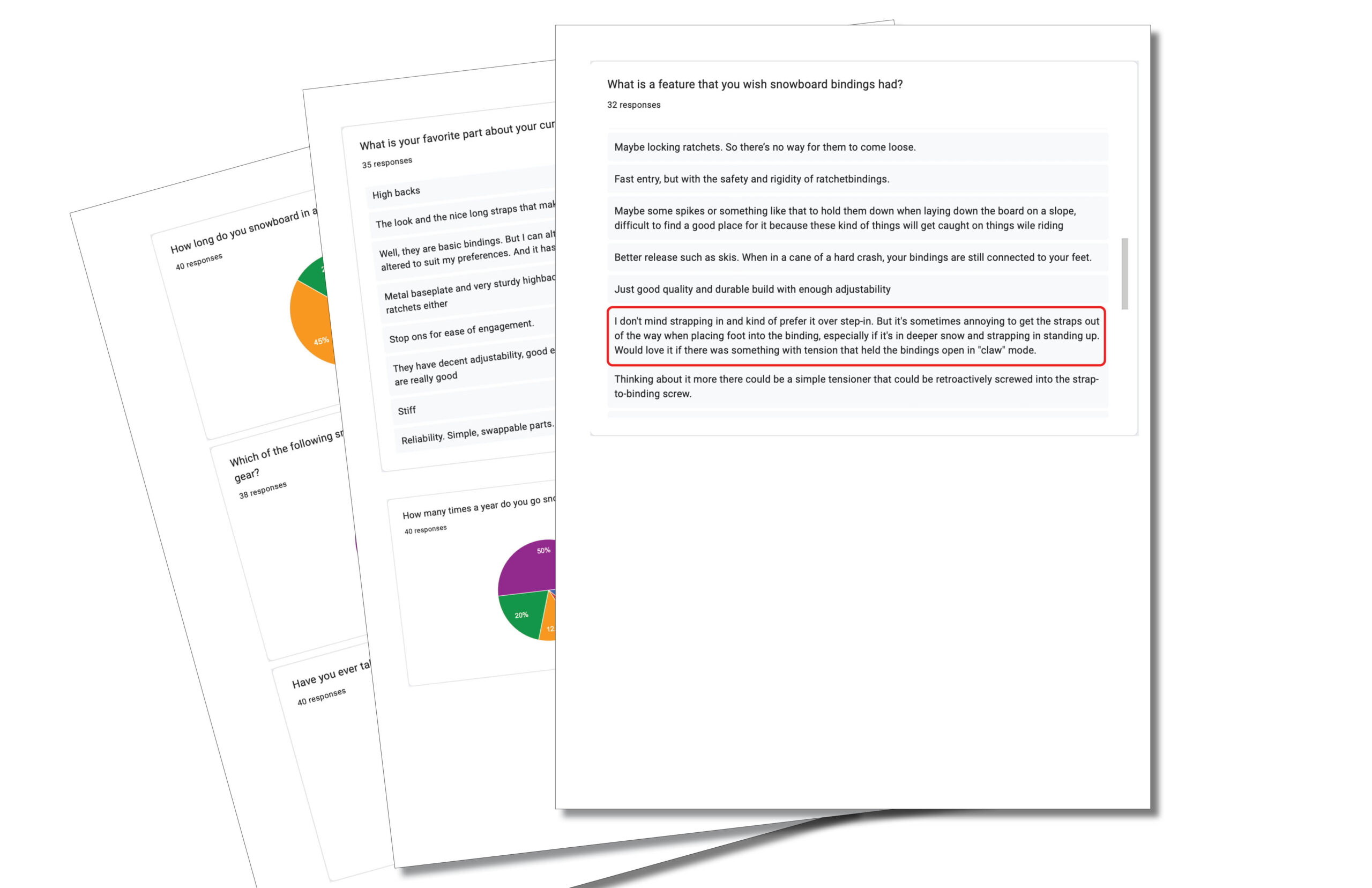

An initial online survey indicated a clear preference among snowboarders, particularly beginners, for maintaining traditional binding architecture without the need for a proprietary boot.

I don’t mind strapping in and kind of prefer it over step-in. But it’s sometimes annoying to get the straps out of the way when placing foot into the binding, especially if it’s in deep snow and strapping in standing up. Would love it if there was something with tension that held the tidings open in “claw” mode.

FIELD OBSERVATIONS

Building on these insights, I conducted field observations and user interviews while snowboarding. This hands-on approach enabled direct engagement with riders, allowing for the discovery of ergonomic considerations in their natural environment. Notably, many riders expressed difficulty in reaching the toe ratchet, often grabbing the board to bring it closer for adjustment. This behavior underscored a common challenge in accessing and securing the toe area of the bindings.

INITIAL CONCEPT SKETCHING

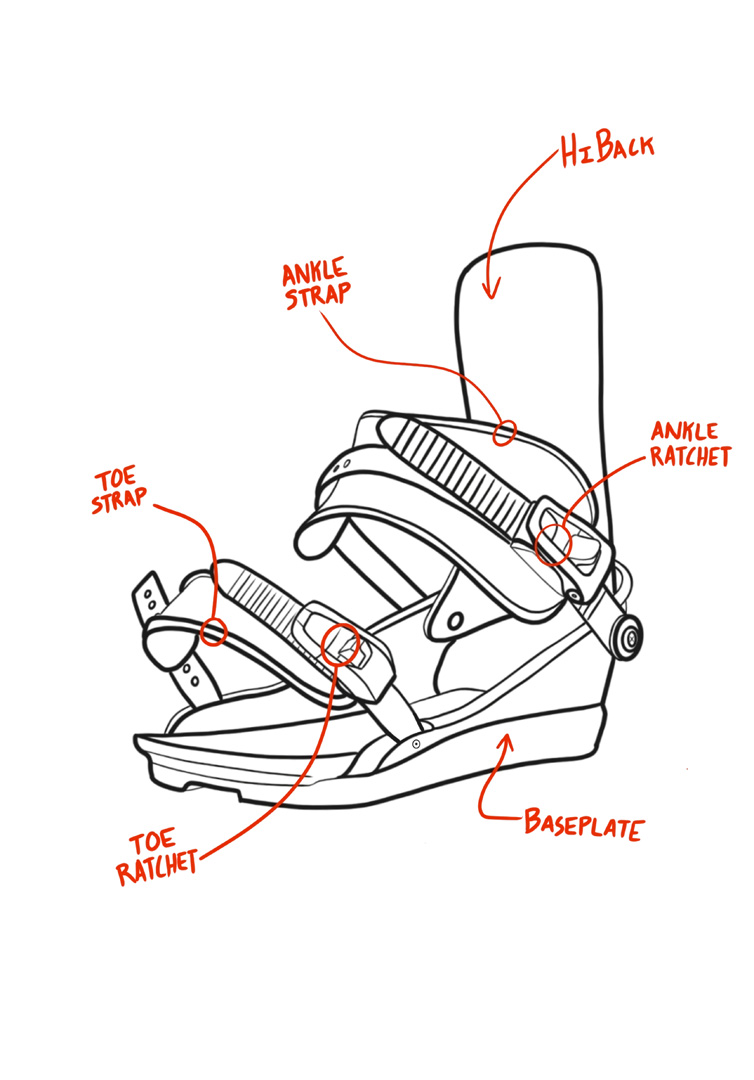

With a clear direction for developing a binding system, I started by sketching the basic architecture of the binding using Procreate.

PROTOTYPING AND EXPLORATION

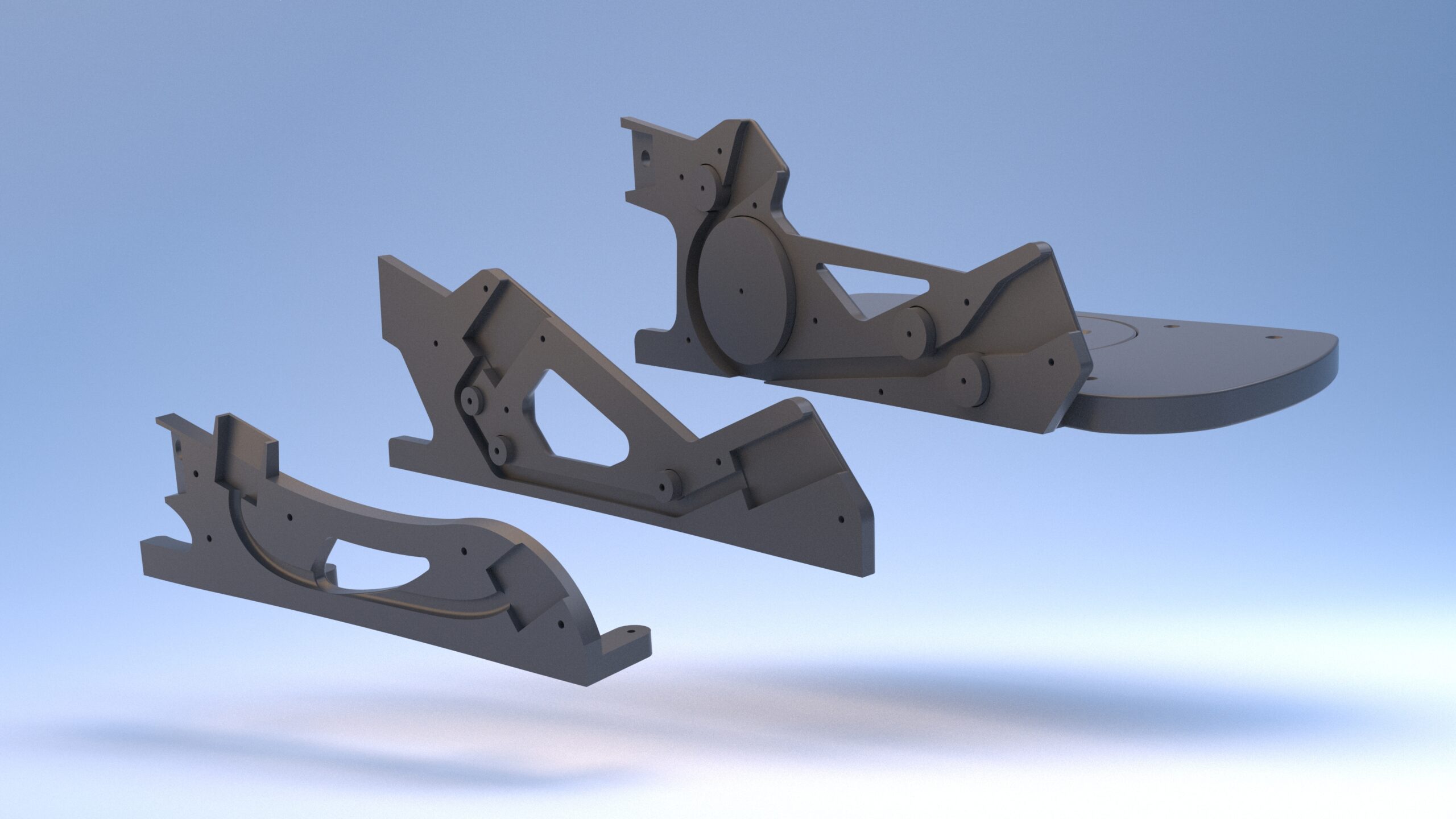

I began by quickly modeling the binding in SolidWorks and 3D-printing a simple frame to test fit, proportions, and basic features. Using paper, tape, and other materials, I explored solutions for eliminating the toe ratchet.

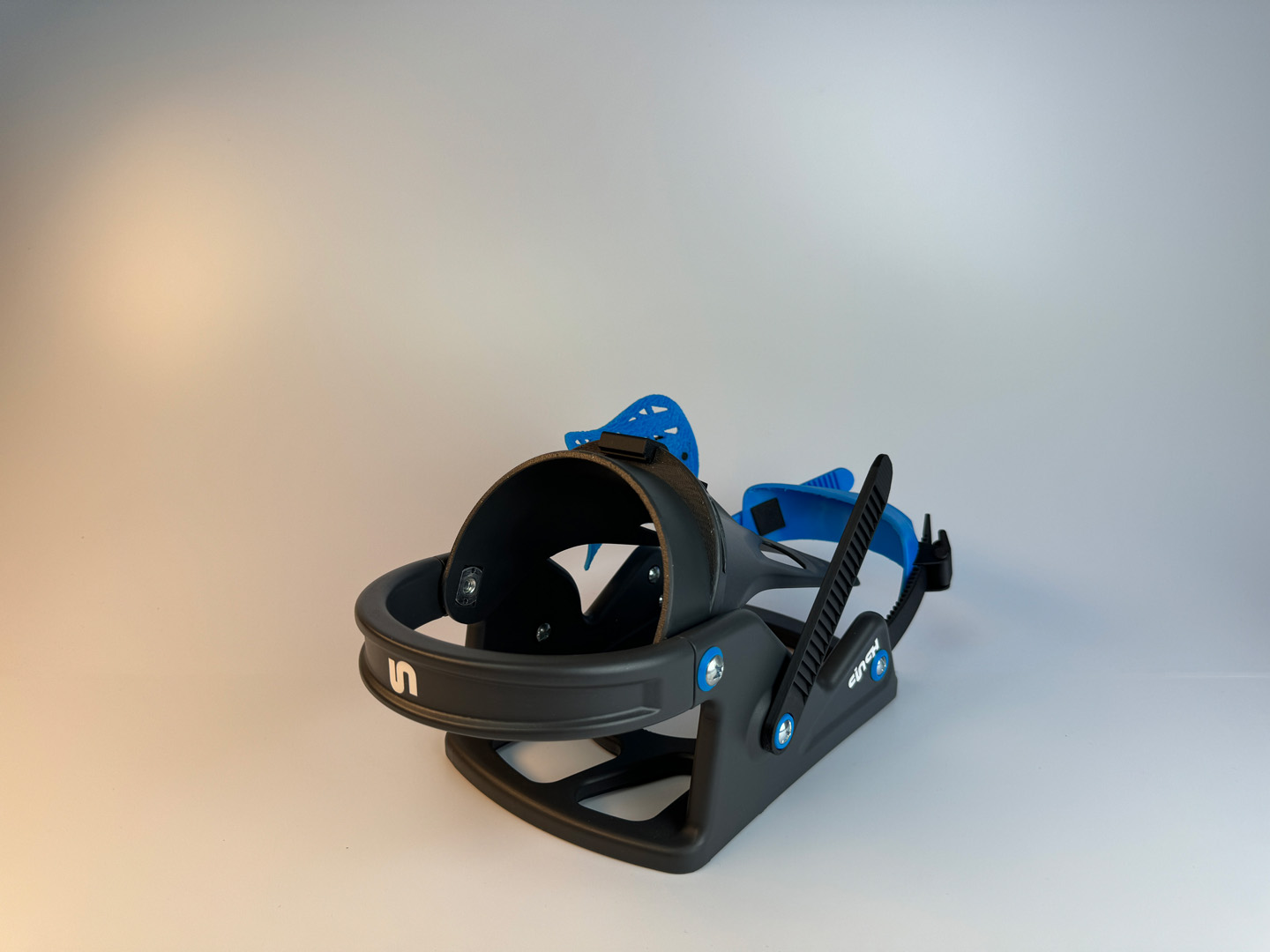

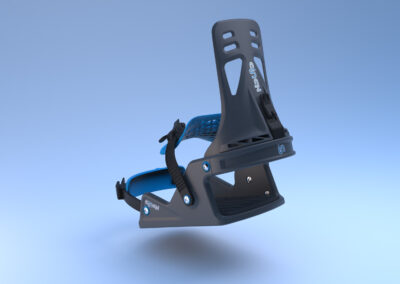

The most promising approach involved a pulley mechanism connecting the heel strap to the toe strap, which became the chosen direction for further development.

ADVANCED

PROTOTYPING

I created another simple 3D-printed frame to validate the pulley system’s feasibility. This frame featured evenly spaced holes for adjustable pulley placement. Concurrently, I learned surface modeling in SolidWorks to accurately design the toe and heel straps for further experimentation.

REFINED TESTING

Shifting the focus to the baseplate sides, I designed a test model with a stationary baseplate and interchangeable sides. This setup allowed me to 3D-print and test different pulley mechanism variations quickly, streamlining the iteration process.

After several iterations, I successfully achieved a mechanism that provided the desired result of smooth and snappy opening and closing of the binding straps.

FINAL DEMONSTRATION MODEL

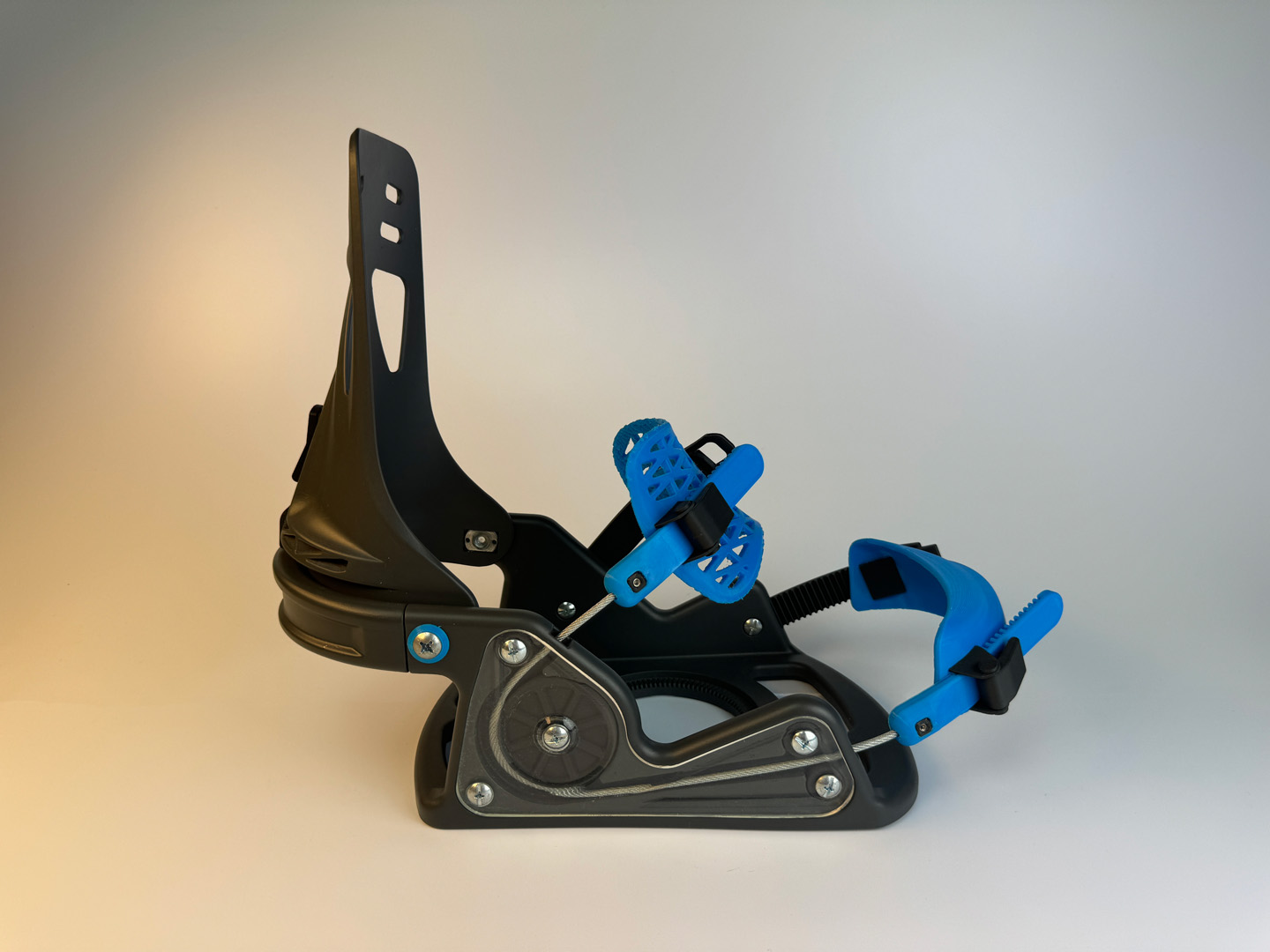

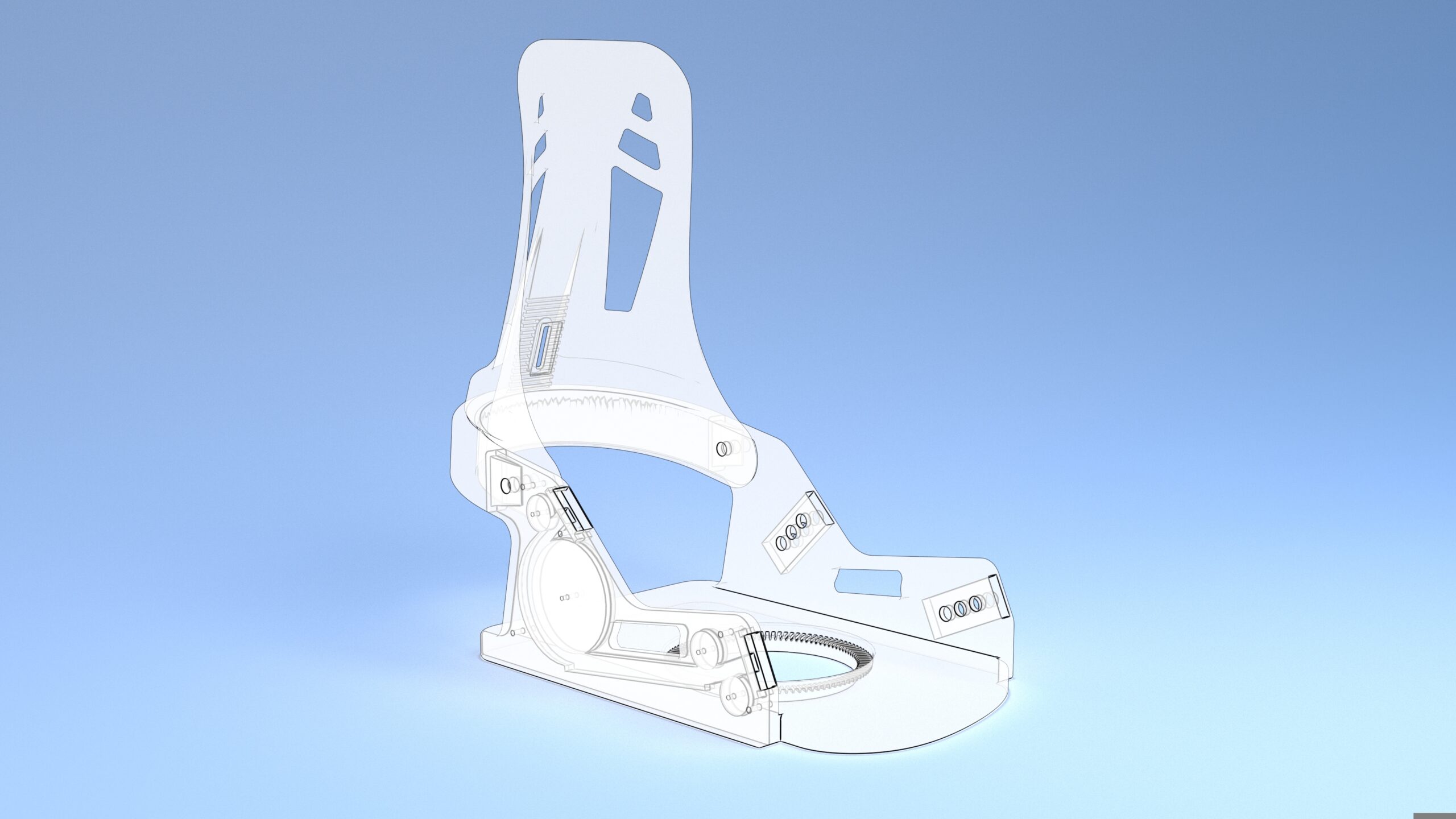

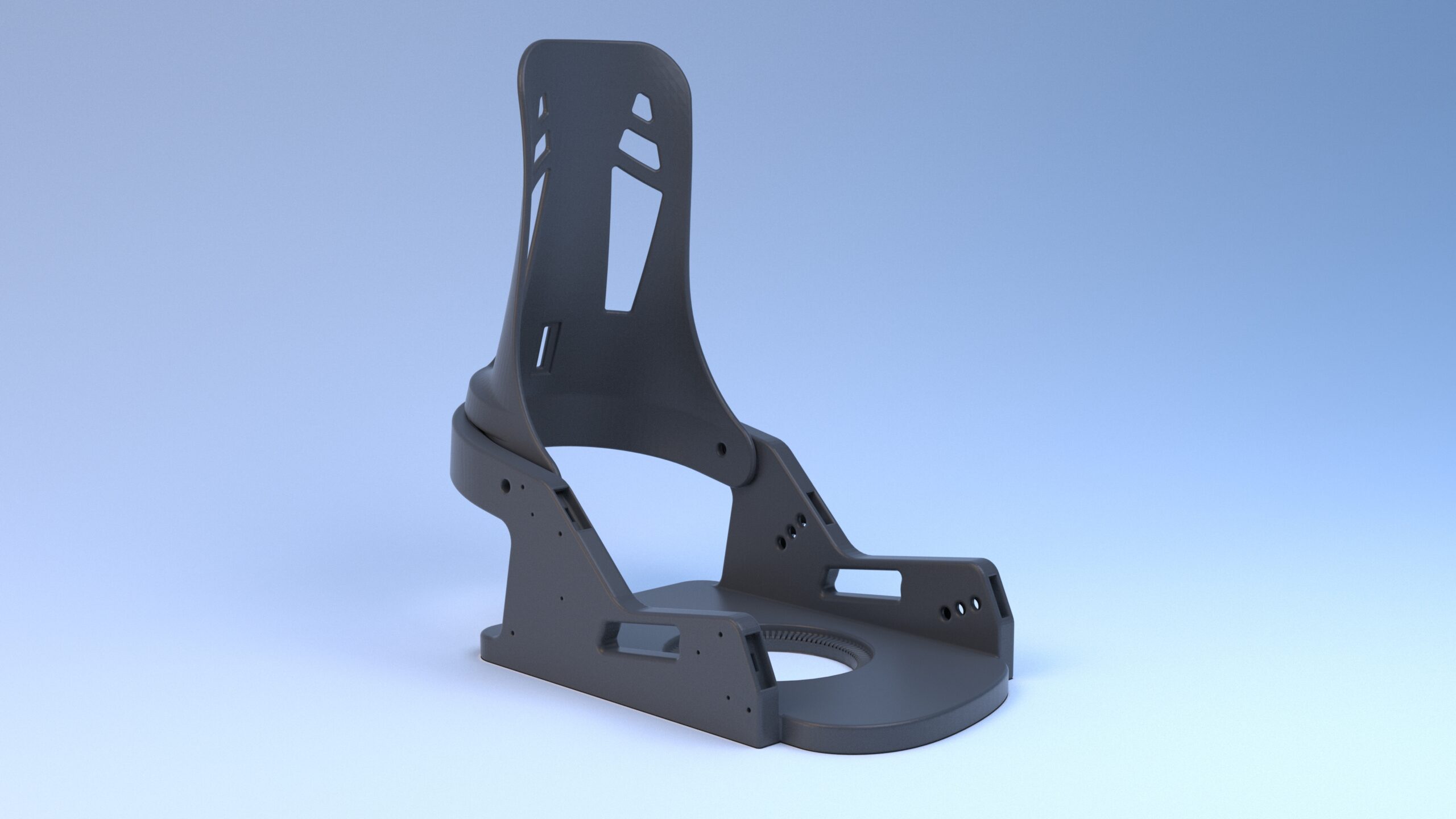

After three iterations of the side panels with mechanisms, I developed a final demonstration model incorporating nearly all the binding features. This model allowed potential users to interact with the binding system and assess its effectiveness in a realistic form. I presented it to classmates, ski shop employees, and random individuals at Eldora Ski Resort for comprehensive feedback.

FINAL design refinement

With feedback in hand, I proceeded to model the final version of the binding. This model integrated all features, mechanics, aesthetics, and branding elements. It includes a transparent side to showcase the mechanical components and thematic design elements that align with the product’s functionality and brand identity.