Ergonomic rotary tool reimagined for a storied powertool brand.

project brief

The project involves disassembling and analyzing a pre-existing rotary tool to understand its internals. The next steps include 3D modeling the components and designing a new housing that aligns with the Makita power tools design language. The goal is to enhance the tool’s performance and ergonomics with the new housing design.

tools

PROCREATE

SOLIDWORKS

KEYSHOT

RHINO

FDM 3D PRINTER

SLA RESIN PRINTER

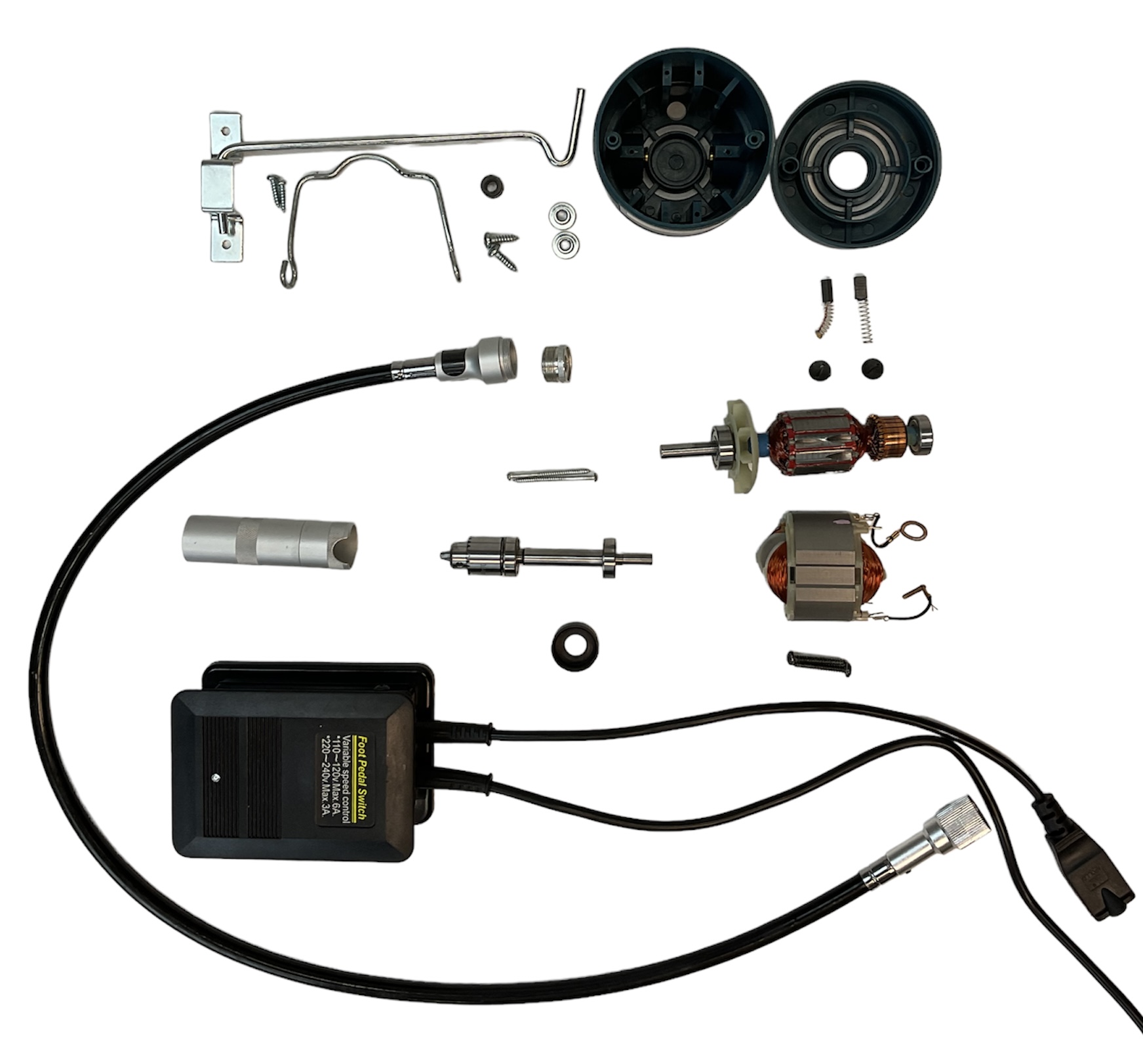

TECHNICAL ANALYSIS

To gain a fundamental understanding of flex-shaft rotary tool construction, I purchased an inexpensive model and disassembled it into its various components. This allowed me to take accurate measurements of each part, which were then used to 3D model a new housing for the tool.

Goal

TASK ANALYSIS

Before designing the handpiece form, it was crucial to conduct field research. I interviewed jewelry craftspeople of various skill levels, as they frequently use flex-shaft style rotary tools. This specific group was chosen for their extensive experience and insights. Through this, I was able to begin to identify potential safety and ergonomic affordances that might set this rotary tool apart from the rest.

PROCESS

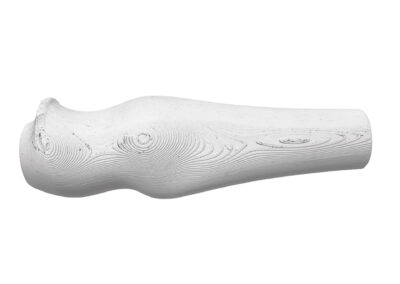

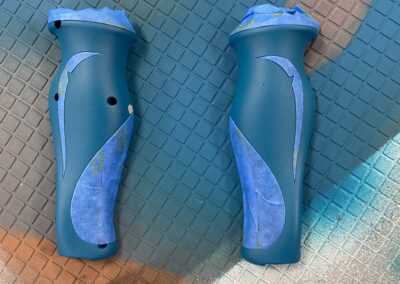

Starting with basic pink foam models, I explored the ergonomics of the rotary tool handpiece. After several iterations and extensive user feedback, I transitioned to SolidWorks to develop 3D-printed shells, refining the ergonomic features with each version.

PRODUCTION AND ASSEMBLY

Once the final housing components for the rotary tool were finalized, I FDM printed the motor housing and SLA printed the handpiece shell on a Form 3 resin printer. This allowed me to capture detail in the sections where it was most necessary.